Little Known Facts About Plastic Injection Molding.

Table of ContentsFascination About Plastic Injection MoldingSome Of Plastic Injection MoldingTop Guidelines Of Plastic Injection MoldingPlastic Injection Molding for Beginners

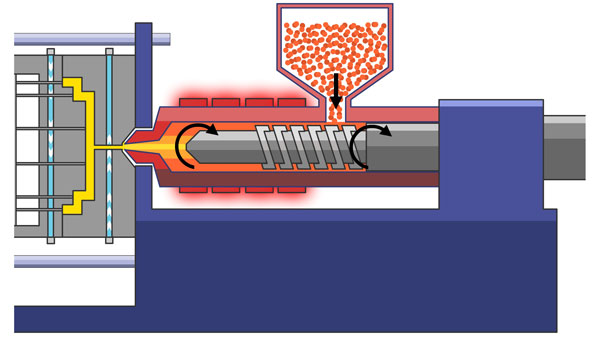

The series of occasions during the shot mould of a plastic part is called the shot moulding cycle. The cycle starts when the mould closes, adhered to by the shot of the polymer into the mould cavity. As soon as the tooth cavity is filled up, a holding pressure is kept to make up for material shrinking.

This creates the screw to withdraw as the following shot is prepared. Generally, the injection portion of the moulding process was done at one continuous stress to fill as well as load the cavity.

As soon as the dental caries is 98% complete, the machine switches over from velocity control to pressure control, where the tooth cavity is "loaded out" at a continuous pressure, where enough rate to reach desired stress is needed. This lets employees manage part dimensions to within thousandths of an inch or better. Like all commercial processes, shot molding can generate mistaken parts, even in playthings.

7 Simple Techniques For Plastic Injection Molding

Tests are typically performed prior to full production runs in an initiative to forecast issues and also determine the suitable specifications to make use of in the shot process.: 180 When loading a new or unknown mould for the very first time, where shot size for that mould is unidentified, a technician/tool setter may perform a test run prior to a full manufacturing run. plastic injection molding.

Once they achieve this, they apply a percentage of holding pressure and also increase holding time till entrance scorn (solidification time) has occurred. Gateway freeze off time can be established by enhancing the hold time, and afterwards weighing the part. plastic injection molding. When the weight of the part does not transform, the gate has frozen and no even more material is infused right into the component.

, very dangerous if the component is being made use of for a security important application as the material has very little strength when delaminated as the materials can not bond. Excess product in thin layer surpassing typical component geometry Mould is over stuffed or parting line on the tool is damaged, also much injection speed/material injected, securing force as well reduced.

The Facts About Plastic Injection Molding Revealed

Loading too fast, not permitting the sides of the part to establish. Likewise mould might be out of registration (when both fifty percents do not centre effectively and component wall surfaces are not the exact same thickness). The given details is the typical understanding, Improvement: The Absence of pack (not holding) stress (pack stress is utilized to pack out even though is the part during the holding time).

To put it simply, as the component reduces the resin separated from itself as there was not sufficient material in the cavity. The space can take place at any kind of location or the component is not limited by the density but by the resin flow as well as thermal conductivity, but it is most likely to occur at thicker locations like ribs or managers.

Knit line/ Meld line/ Transfer line Discoloured line where two circulation fronts meet Mould or worldly temperature levels set too reduced (the product is cool when they fulfill, so they do why not look here not bond). Time for change in between shot as well as transfer (to packaging as well as holding) is as well very early. Turning Distorted component Air conditioning is also brief, material is too hot, lack of cooling around the device, inaccurate water temperature levels (the parts bow inwards towards the warm side of the device) Irregular reducing between locations of the part.

Some Of Plastic Injection Molding

125 inch wall surface density is +/- 0. The power needed for this procedure of shot moulding depends on lots of points and also differs in between products made use of. Below is a table from web page 243 of the very same reference as previously pointed out that ideal highlights the characteristics appropriate to the power required for the most frequently made use of products.

In addition to installing assessment systems on automatic tools, multiple-axis robotics can remove parts from the mould as well as position them for further procedures. Details circumstances consist of eliminating of components useful reference from the mould quickly after the parts are produced, in addition to applying equipment vision systems. A robot grips the component after the ejector pins have actually been encompassed free the part from the mould.

Why is shot molding equipment production so efficient? What is Injection Molding?

The shot molding device makes use of tailor-made molds to load them out according to specs, creating the same copies that can be tailored in a variety of methods. What's more, shot molding is a very functional process, enabling a wide variety of different materials and also finishes, that makes it a prominent option in plenty of markets with completely different goals and also needs.